News

What is the function of the wire diameter compensation function of the digital tension tester?

So some digital tension testers on the market have a wire diameter compensation function, and some digital tension testers do not have wire diameter compensation function. What is the difference?

the digital tension tester is a mechanical measurement tool used to measure the tension of the wire. It mainly uses the principle of three guide wheels to realize the tension measurement. The material to be tested passes between the three measuring guide wheels, and the trigonometric function algorithm is used to get the tension on the line. the enveloping angle formed when the wire passes through the three guide wheels is the key factor for calculating the final tension value. Therefore, when wires of different wire diameters pass through three guide wheels, due to the different thicknesses of the wires, the angles formed will inevitably be different, which will affect the final tension value calculation. Therefore, when designing a digital tension tester, compensation must be made. There are relatively few brands with wire diameter compensation on the market. For example, the universal tension meter NT series digital tension tester provided by Shenyang Betten Technology Co., Ltd. is a digital display tension tester with wire diameter compensation and automatic zero-clearing functions. Models are NT-1000, NT-2000, NT-5000, etc., suitable for measuring the tension of copper wire, yarn, enameled wire, steel wire and other materials.

The NT series has 10 kinds of tension ranging from 1.0-200.0cN to 10.0-100.0daN. The width of the measuring head varies with different ranges.

Features:

1. The patented technology automatically resets the meter to zero , which improves the measurement accuracy and facilitates measurement.

2. Equipped with a wire diameter compensator, which compensates errors caused by different wire diameters and improves measurement accuracy

3. Equipped with lead frame and guide wheel movement structure, it is easy to capture the tested material.

4. V-groove aluminum measuring guide roller with ball bearing.

5. Rugged, non-slip aluminum case, resistant to electrical interference.

6. LIPO lithium-ion polymer battery (about 13 hours of continuous operation).

7. The tested material, the guide roller, and the screen are located on the same plane. During the test, the test data, the status of the guide roller and the tested material can be seen.

8. A maximum of 10 materials can be accurately calibrated. With the wire diameter compensator, the tested wire diameter range is larger.

9. character menu setting interface, easy to operate.

10. According to different ranges and needs, the measurement value display unit can be selected g, kg, c N, N, daN, lb

11. It can record the maximum value, minimum value, peak value and average value in the measurement process, and can also store 10 independent measurement values.

12. Programmable setting of the maximum and minimum value of the trend status bar, clearly determine the range of tension change, and have the advantages of mechanical instrument trend display.

13. Provides fine adjustment of display results. If There is a slight deviation between the material measured on site and the standard calibration material, and accurate values can be displayed without recalibration.

14. Function settings can be protected by passwords to improve setting security.

15. Betten tensiometer provides two display modes, taking into account the advantages of accurate electronic tensiometer reading and mechanical tensiometer trend display.

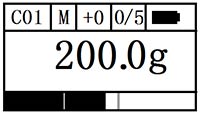

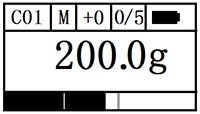

-Digital display -Digital display plus tension change trend bar

Model NT

Model | Tension range | Measuring head width | Diameter range | Calibration materials (Polyamide Monofilament) | wire diameter compensation |

NT-200 | 2.0-200.0 cN | 65mm | 0.05-0.15mm | φ0.12mm | yes |

NT-500 | 5.0-500.0 cN | 65mm | 0.05-0.2mm | φ0.12mm+φ0.2mm | yes |

NT-1000 | 10-1000 cN | 65mm | 0.1-0.5mm | φ0.2mm+φ0.4mm | yes |

NT-2000 | 20-2000 cN | 116mm | 0.3-0.7mm | φ0.4mm+φ0.7mm | yes |

NT-2500 | 25-2500 cN | 116mm | 0.3-0.7mm | φ0.4mm+φ0.7mm | yes |

NT-5000 | 50-5000 cN | 116mm | 0.4-1.0mm | φ0.7mm+φ1.2mm | yes |

NT-10K | 0.1-10.0daN | 116mm | 0.7-1.2mm | φ0.8mm+φ1.0mm | yes |

NT-20K-F | 0.2-20.0daN | 116mm | 1.0-1.8mm | φ1.2mm | yes |

NT-30K-F | 0.3-30.0daN | 216mm | Customer specified wire diameter range | Customer specified materials | yes |

NT-50K-F | 0.5-50.0daN | 216mm | Customer specified wire diameter range | Customer specified materials | yes |

NT-60K-F | 0.6-60.0daN | 216mm | Customer specified wire diameter range | Customer specified materials | yes |

NT-100K-F | 1-100daN | 216mm | Customer specified wire diameter range | Customer specified materials | yes |

Unit conversion: 1daN = 10N = 1.02kg 1cN = 1.02g

Optional accessory special lever (Order code F Example: NT-1000-F, standard for NT-20K to NT-100k,recommended for NT-10K)

Measurement roller options

Standard guide roller 1000 m / min Hardened aluminum Standard guide wheel drawing.

Coder UB guide roller 1000 m / min Hardened aluminum Selection code UB, For example NT-1000-UB

UB drawing

Coder TC guide roller 1000m / min Ceramic coated special steel Selection code NT-1000-TC

TC drawing

NT shipment includes tension meter, portable meter box, charger, manual, certificate of compliance.

Specifications:

Accuracy : (factory calibration material) 1% full scale (FS), (other materials) 3% FS.

Display update frequency : 0.5 seconds

Optional units: gf, cN, N, kgf, daN, LB (switchable units are different for different ranges)

Adjustable range: The displayed value can be adjusted within ± 10 steps of 1% of full scale according to the site requirements

Line speed: 1000m / min

Stored value: Maximum, minimum, maximum peak, minimum peak, average

Display : Dot-matrix LCD

Shell size: 76 × 46 × 275mm

Power : Lithium-ion rechargeable battery, continuous working for about 13 hours

Operating temperature : 10-45 ° C, 90% relative humidity or less

Accessories : Instrument, instruction manual, certificate, charger, instrument box

Applications: stranding machine, winding machine, wire cutting machine, carbon fiber winding equipment, optical fiber winding equipment, optical cable

Production equipment, glass fiber winding equipment, steel cord production equipment, tire production equipment, wire rope production equipment.

Sorted by industry

News

Contact Us

Contact: China tension meter manufacturer BETTEN Technology

Phone: 13911001672

Tel: +86-24-24754482

E-mail: info@betten-tech.com

Add: Shenyang Shenbei International Science and Technology Cooperation Industrial Park